COMPA Repairs is applicable in:

- Ships and in their hull and piping systems

- FPSO, rigs and other offshore process plants

- Onshore plants

- Infrastructure, bridges and buildings

COMPA Repairs is a result of extensive experience in ship design and engineering.

The method features application of carbon and glass fibres mixed with epoxy resin/adhesive onto a damaged surface. By curing, the resin hardens and bonds to the surface permanently, impregnating also the fibres that reinstate the strength of the damaged part. It creates a solid new layer of material that provides full watertightness.

Cost-efficient compared to traditional repairs

Safe, no hot works involved

Done during voyage or port operations

Applicable to any shape

Applicable to anything reachable by hand

Durable patch is resistant to osmosis

High-pressures, salt, dust, mud, or liquids do not pose a challenge

Low added weight

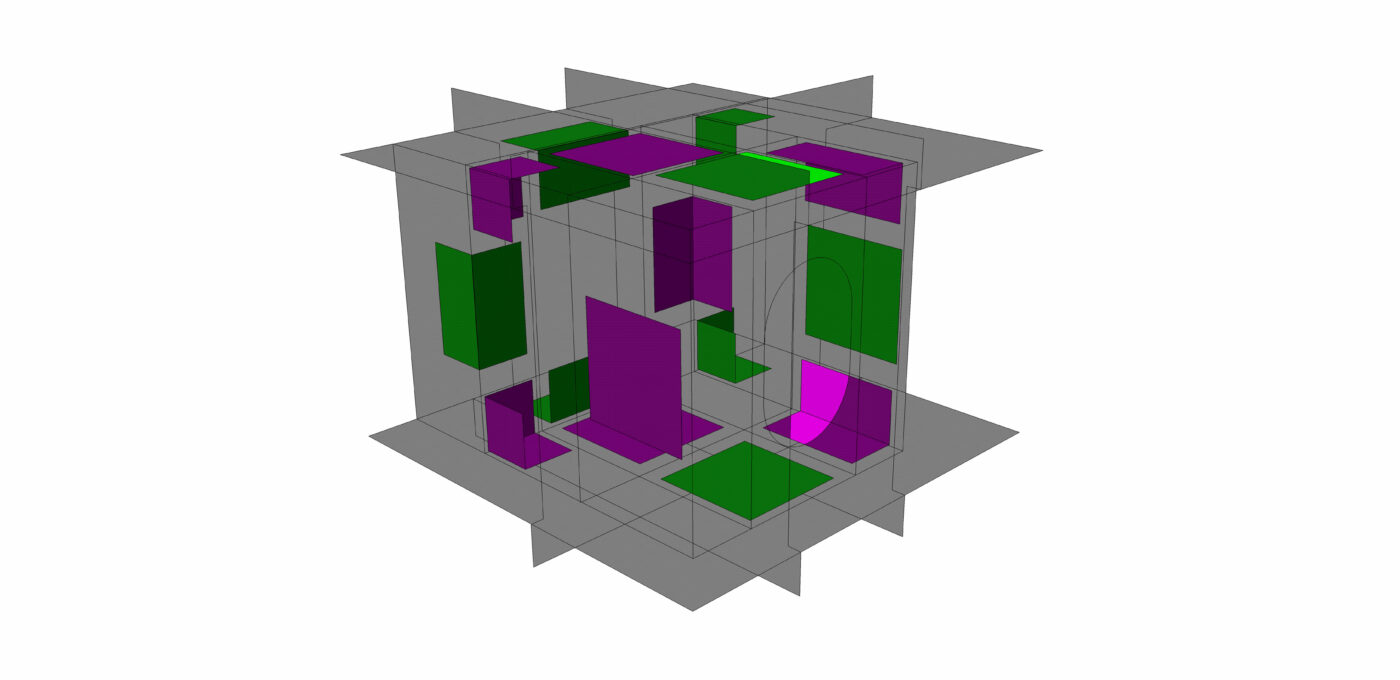

Prior the repair process, our engineers and composite experts investigate the damage parameters and then develop a repair plan using COMPA Repairs software and CATIA software.